Pasta manufacturing

Pasta is a universally enjoyed food, and almost every country serves a type of noodle.

The popularity of pasta can be attributed to several factors: it is easily manufactured, it takes up little storage space, it is easy to cook, and it is rich in complex carbohydrates.

Ancient Etruscan meals of gruel and porridge were eventually replaced with more appetizing unleavened bread cakes. Food historians believe these cakes may have been the precursor to pasta.

Opinions about where the noodle originated vary.

First attested in English in 1874, the word pasta comes from Italian pasta, in turn from Latin pasta "dough, pastry cake", itself the latinisation of the Greek παστά (pasta) "barley porridge", in turn from παστός (pastos), "sprinkled with salt, salted".

The invention of the first tomato sauces dates back from the late 18th century: the first written record of pasta with tomato sauce can be found in the 1790 cookbook L'Apicio Moderno by Roman chef Francesco Leonardi

It is to be noted that the idea of using tomato sauce to give pasta its flavour was revolutionary since it was originally eaten plain.

It was eaten with the hands as only the wealthy could afford eating utensils.

The consumption of pasta has changed over time; it was once a small, simple item, but it is now often eaten in much larger portions and as part of complex, sophisticated dishes.

Factors such as low prices and ease of cooking contribute to the growing popularity of this staple ite

Trends - Retail sales of pasta have witnessed growth in both value and volume terms in 2011 and 2012. Trends - Retail sales of pasta have witnessed growth in both value and volume terms in 2011 and 2012.

Pasta’s positioning as a quick and low-cost home meal helped the category to maintain sales during the slow economic recovery.

Consumers in North America had turned to cooking pasta at home during the recession.

Even as consumers began to eat out again, pasta’s ease of cooking allowed it to remain a favorite at home.

Price increases in 2011 and 2012 have also helped to spur retail sales growth. Retail volumes are set to grow by 1% in 2012 and retail value sales by 2% in current terms.

Competitive landscape - Private label continues to lead pasta in 2012 with a value share of 22%. The US economic recession which occurred during the review period was beneficial to private label’s growth. Many consumers still rely on private label pasta as a cheap and convenient meal option.

The slow economic recovery, favorable price points, improved quality and better-for-you offerings have contributed to private label’s continued success over 2011/2012.

Private label pasta sales are set to reach US$751 million in 2012, up 4% from 2011. Makers of private label pasta have successfully imitated Barilla PLUS and Ronzoni Garden Delight by introducing their own better-for-you variants.

Prospect - Over the forecast period pasta is anticipated a slow but steady constant value CAGR of 1% and marginal volume growth. Slow economic growth will encourage consumers to see pasta as an inexpensive and convenient meal option.

Consumers will also be drawn to better-for-you pasta products.

Pasta marketers have been effective in promoting their products as a healthy part of a balanced diet.

|

|

|

|

|

The Italian explorer Marco Polo has been commonly credited with bringing the noodle back to Italy from his travels in the Orient during the 1300s.

However, some contend that a close examination of Polo's papers reveals that he reported enjoying a certain type of noodle in China, comparing it favorably to the pasta he was accustomed to eating in Italy.

Nevertheless, it is true that Chinese noodles have been around for centuries.

The vermicelli-like transparent noodles are made from the paste of germinated mung beans and are usually soaked in water before they are boiled or fried The vermicelli-like transparent noodles are made from the paste of germinated mung beans and are usually soaked in water before they are boiled or fried

(Pasta has not always been prepared by boiling, in fact, boiled noodles were once considered a relatively bland meal. Frying or grilling were the preferred preparations). Koreans claim to have taught the Japanese how to make soba noodles in the 12th century, using Chinese buckwheat grown in the northern regions where rice paddies could not survive.

Early French writers also mention a dish called pastillum, essentially a ravioli-like pouch filled with meat. However, the Italians have staked the claim so vehemently that today we generally think of pasta dishes as Italian in origin. In fact, the word "pasta" comes from the Italian phrase "paste (dough) alimentari (relating to nourishment)."

The first industrial production of pasta occurred in Naples in the early 15th century. The first industrial production of pasta occurred in Naples in the early 15th century.

The site was chosen for its naturally fluctuating temperatures, sometimes as much as four times a day, which provided the hot and cold temperatures necessary for drying.

Mechanical drying was not invented until 1800. (Gragnano is a hill town edged between a mountain crest and the Amalfi Coast, home to some of the best dried pasta in Italy-Gragnano's main street was laid out expressly to capture the mountain breeze mixed with sea air back when pasta makers hung spaghetti on drying rods like laundry).

Pasta is made from a mixture of water and semolina flour.

Semolina is a coarse-ground flour from the heart, or endosperm, of durum wheat, an amber-colored high protein hard wheat that is grown specifically for the manufacture of pasta.

With a lower starch content and a higher protein content than all-purpose flours, semolina flour is easily digested.

Farina, rougher granulation of other high-quality hard wheat, is also used to make some pastas.

The semolina and farina flour are enriched with B-vitamins and iron before they are shipped to pasta plants.

Mixing and kneading - The semolina is stored in giant silos that can hold up to 150,000 pounds (68,100 kg). Pipes move the flour to a mixing machine equipped with rotating blades. Mixing and kneading - The semolina is stored in giant silos that can hold up to 150,000 pounds (68,100 kg). Pipes move the flour to a mixing machine equipped with rotating blades.

Warm water is also piped into the mixing machine.

The mixture is kneaded to a lumpy consistency.

Flavoring and coloring - Eggs are added to the mixture if the product is an egg noodle. Flavoring and coloring - Eggs are added to the mixture if the product is an egg noodle.

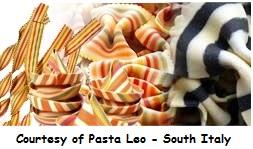

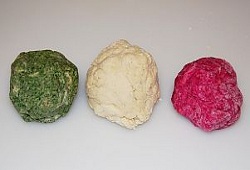

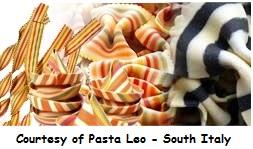

If pasta is to be a flavored variety, vegetable juices are added here.

A tomato or beet mixture is added for red pasta, spinach for green pasta, carrots for orange pasta.

Herbs and spices can also be folded in for additional flavoring.

Rolling - The mixture moves to a laminator where it is pressed into sheets by large cylinders.

A vacuum mixer-machine further flattens the dough while pressing air bubbles and excess water from the dough to reach the optimum water content of 12%.

Pasteurization - The roll of dough moves through a steamer, which heats the dough to 220°F (104°C) in order to kill any existing bacteria.

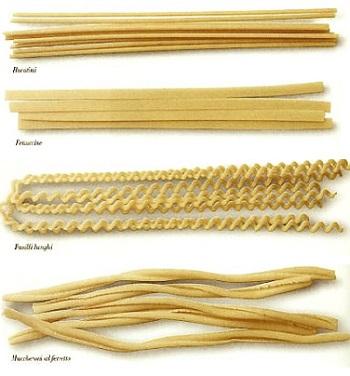

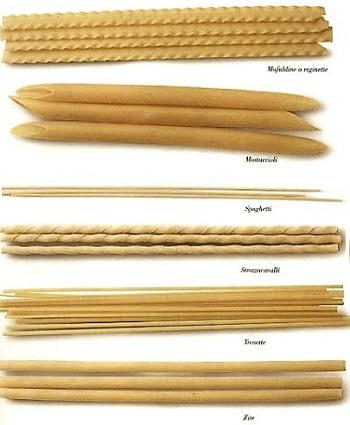

Cutting - Depending on the type of noodle to be produced, the dough is either cut or pushed through dies. Cutting - Depending on the type of noodle to be produced, the dough is either cut or pushed through dies.

Ribbon and string-style pasta—such as fettucine, linguine, spaghetti, and capellini (angel hair)—are cut by rotating blades.

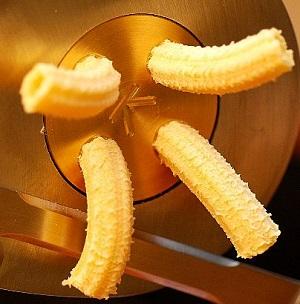

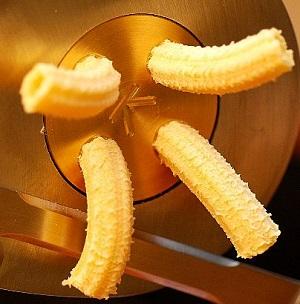

To make tube or shell-shaped pasta such as rigatoni, ziti, elbow macaroni, and fusilli, the dough is fed into an extruder which then pushes it through metal dies.

Contrary to industrial pasta makers who use plastic dies for extruders (they are cheaper and faster to replace) which tends to give the finished product a smooth surface, small artisan pasta makers use bronze dies, leaving the pasta rough so the sauce can better stick to it.

The size and shape of the holes in the die determine the type of pasta.To make vermicelli and capellini, the pasta dough is pushed through holes between 0.8-0.5 mm in diameter. The size and shape of the holes in the die determine the type of pasta.To make vermicelli and capellini, the pasta dough is pushed through holes between 0.8-0.5 mm in diameter.

The cutting machine then cuts the pasta into lengths of 10 inches (250 mm) and twists it into curls. Spaghetti ranges from 1.5-2.5 mm in diameter and is left straight.

Tortellini (filled pasta rings) are made on a separate machine.

The machine cuts small circles from a roll of dough. A bucket of ricotta cheese mixture drops a pre-measured amount of cheese onto the circle of dough. The dough is then folded over and the two ends are joined to form a circle.

To make ravioli (filled pasta squares), premeasured quantities of cheese filling are dropped by machine at pre-measured intervals on a sheet of pasta. Another sheet of pasta is placed over this sheet as it moves along a conveyer belt.

The two layers then pass under a cutting machine that perforates the pasta into pre-measured squares.

Drying - The pasta is placed in a drying tank in which heat, moisture, and drying time are strictly regulated. The drying period differs for the various types of pasta. Drying - The pasta is placed in a drying tank in which heat, moisture, and drying time are strictly regulated. The drying period differs for the various types of pasta.

It can range from three hours for elbow macaroni and egg noodles to as much as 12 hours for spaghetti.

The drying time is critical because if the pasta is dried too quickly it will break and if it is dried too slowly, the chance for spoilage increases.

The oxygen level in the tank is also regulated, and lab technicians test frequently for salmonella and other bacteria.

Careful handling of the pasta during the drying period is also crucial. Spaghetti is the most fragile of the noodles and is therefore hung high above the floor.

Packaging - Fresh pasta is folded in pre-measured amounts into clear plastic containers. As the containers move along a conveyer belt, a plastic sheet covers each container and is sealed with a hot press. Packaging - Fresh pasta is folded in pre-measured amounts into clear plastic containers. As the containers move along a conveyer belt, a plastic sheet covers each container and is sealed with a hot press.

At the same time, a small tube sucks the air of the container and replaces it with a mixture of carbon dioxide and nitrogen to prolong the product's shelf-life.

Labels listing the type of noodle, nutritional information, cooking instructions, and expiration date are attached to the top of the containers.

Dried pasta is loaded, either manually or by machine, into stainless steel buckets (usually of heavy gage type 304) which move along a conveyer belt to the appropriate packaging station.

The pasta is measured by machine into pre-printed boxes, which also list the type of noodle, ingredients, preparation, and expiration date. Again, careful handling is important.

For example, because lasagna noodles are particularly fragile, workers place them on metal slides that ease the pasta into boxes. The boxes are then sealed by machine.

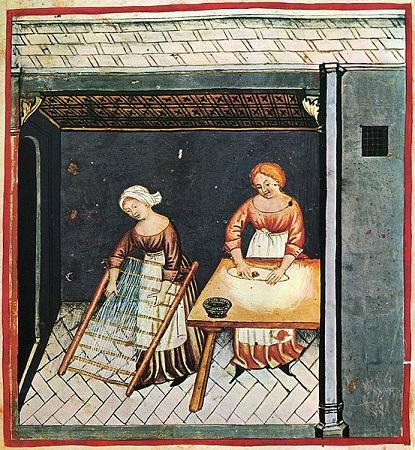

Homemade Pasta - The popularity of pasta has spread to the home-cooking arena. Pasta-rolling machines and pasta cookbooks are available at house-wares stores and in cooks' catalogs. Homemade Pasta - The popularity of pasta has spread to the home-cooking arena. Pasta-rolling machines and pasta cookbooks are available at house-wares stores and in cooks' catalogs.

The recipe for homemade pasta is similar to the industrial process with the exception that eggs are generally used in all home pasta recipes. Sometimes oil is added to the mixture, particularly if a lesser grade of flour is used.

The flour is measured out onto a wooden or marble surface and formed into a mound with a well in the center. The flour is measured out onto a wooden or marble surface and formed into a mound with a well in the center.

Eggs, water, oil and any other desired ingredients are poured into the well and mixed lightly with a fork. Then, beginning from the outside of the mound, the flour is incorporated into the center.

|

|

|

|

The dough is kneaded for approximately five minutes until a smooth, elastic ball is achieved. Rolling the dough into sheets is done with a long Italian-style rolling pin or with a rolling machine.

Most rolling machines have attachments for cutting the dough into various forms of pasta such as spaghetti, fettucine, lasagna, or ravioli.

The dough can also be cut by hand using a sharp knife or rolling blade. The dough can also be cut by hand using a sharp knife or rolling blade.

Specially marked rolling pins that imprint squares on the dough or ravioli trays can be used for making stuffed pasta.

Extrusion machines for making tube-style pasta such as rigatoni or fusilli can also be purchased for home use. |

|

|

Pasta manufacturing equipment

PAMA PARSI MACCHINE S.r.l.

PAMA PARSI MACCHINE S.r.l.

Via Maremmana III, n. 55

00030 San Cesareo (RM) Italy

WWW

Pasta manufacturing machines, extruders and pasta dies, dough mixers, dough sheeters, laminators, gnocchi, ravioli makers and ravioli molds, pierogi machines, multi-function pasta machines, pasta equipment, factory training and large industrial pasta manufacturing machines.

The fresh pasta business in recent years is fast growing, this is mainly due to the increased focus on healthy eating and the pursuit of traditional and homemade products.

To develop this type of activity is therefore necessary to pamper clients with quality products in order cater to the needs of this fast growing niche.

Do you want to open a fresh pasta shop all included? If you like what you do you , you are already halfway there .

It will help if you could provide some information about your budget and size of the premises (sq ft).

Type & Shapes:

will it be stuffed, long, short cut or minute?, decorative shapes or ribbon cut? ... who do you intend to sell to?

Will it be dry or fresh pasta?

For instance, will you need packaging equipment?

You will also need to conduct a market analysis (population in your area-growth pattern-are you in a upscale location?).

Who will be your customer?Specialty/gourmet/stores, catering sector, your local Italian restaurants, farmers market.

Who would be your direct competitor?

Pasta types

The pasta machine below would be ideal for Restaurants - Catering business.

It has been a big hit in the Italian Agritourism sector. For those interested the Company also provide informative seminars on its premises.

The Future - Pasta continues to increase in popularity. The National Pasta Foods Association estimates that the average American will eat more than 29 pounds (13 kg) of pasta each year by the turn of the century.

Highly rated for its nutritional value, pasta is an ideal meal for people who are paying more attention to their dietary intake. In addition, people are finding less time to prepare meals, and pasta is easily made.

Pasta manufacturers are responding to this demand by introducing a wide variety of dried and fresh pastas.

One recent innovation is no-boil pasta that is partially cooked at the plant, making this already easy-to-prepare food even simpler to bring to the table at mealtime.

New lines of fat - and cholesterol - free ravioli are on the market as well as organically - grown pasta products.

Two new grains, South American quinoa and Egyptian kamut, are being used to make wheat-free pasta.

Eccellenze Calabresi

From Calabria with amore

|

| Ragu Napolitano with Italian Sausage and Pasta Recipe |

|

Frank shows you how to make a meal your sweetheart will always remember! "Sunday Sauce" .

Time to prep: 30 minutes - Time to cook: 3 hours - Serves: 6-8 as a main course.

|

SHOPPING LIST:

8 Italian Sausages (hot, mild or combined)

3 lbs. beef short ribs or pork ribs

4 Tbsp. olive oil

1/2 med. onion, peeled and chopped

3 cloves fresh garlic, finely chopped or pressed

1/2 tsp. red pepper flakes (optional)

1/2 cup dry red wine

2-28-oz. cans Italian style plum tomatoes, with juice, squeezed by hand or broken up in skillet with a wooden spoon.

10 basil leaves, torn

1 dried bay leaf

1 lb. Rigatoni pasta or pasta of choice

Salt & freshly ground pepper

6-8 tbsp. freshly grated Pecorino Romano cheese

Meat Options for sauce: Meat balls, Chicken, Braciole, bone-in Pork Ribs |

| |

LET'S COOK .

1- Pre-heat oven to 225°. In a large 13 quart pot (cast iron, such as Le Creuset or similar), heat 2 Tbsp. olive oil on medium heat. Salt & pepper ribs on all sides and cook until brown on all sides, set aside.

2 - Then brown the sausages on both sides. No need to cook through, the sausages will finish cooking in the sauce. Do this in batches, so you don't crowd the pot. Remove the sausages from the pot and set aside. Add 2 Tbsp. olive oil to the pot, add the onion, garlic, red pepper flakes and 1/2 tsp. salt and cook until onion is soft, 8-10 minutes.

3 - Add the wine to deglaze the pot, scraping up the brown bits on the bottom. Cook until the wine evaporates by half, one minute or two.

Add the crushed tomatoes, bay leaf, 3 leaves of torn basil, salt and pepper to taste.

4 - Return only the ribs to the pot. Bring sauce to a boil then reduce heat to a simmer. Cover with lid and place in oven for 1 hour. While the ribs are slow roasting, cover the browned sausages and refrigerate. After 1 hour, add the sausages to the pot and cook with the lid off for the last 2 hours.

5 - Bring 5 qts. of water to a boil. Add 2 Tbsp. salt to boiling water, add the Rigatoni and cook until al dente -- about 12-14 minutes, or according to the package instructions.

6 - While the pasta is boiling, remove the meat from the sauce, and place on a large serving platter, cover with foil and keep warm in the oven on very low heat. The sauce should be reduced enough to coat the back of a spoon. If needed, reduce further on medium heat on top of the stove, until thickened. Reserve about 2 cups of sauce for the meat and keep warm.

7 - Drain the pasta and add to the sauce. Toss the pasta in the sauce to ensure each piece is coated. Add the torn basil and a drizzle of good olive oil off the heat, mix well. Serve immediately with freshly grated Pecorino Romano cheese.

Top the meat with the reserved warm sauce and serve after the pasta course or together if you choose...and Buon Appetito

|

| |

La vetrina ideale per promuovere i vostri prodotti e servizi sul mercato Nord Americano ma che potrebbe essere un punto di visibilità anche nei vari mercati internazionali.

AZIENDE - PRODUTTORI - STRUTTURE RICETTIVE - GUIDE TURISTICHE - TOUR OPERATORI

Ai nostri visitatori piace il Sud Italia, vuoi dire loro qualcosa?

Paesi di provenienza dei visitatori al nostro sito in ordine numerico

Stati Uniti - Canada - Italia - Gran Bretagna - Australia - China - Germania - Francia - Nuova Zelanda - Olanda

Coloro interessati ad inserire la loro attivita'/azienda/ nel sito

sono pregati di mettersi in contatto usando il modulo sottostante .

Per saperne di piu'...

|